• Forced and Self Excited Vibrations

• Torque Spindle Dynamics

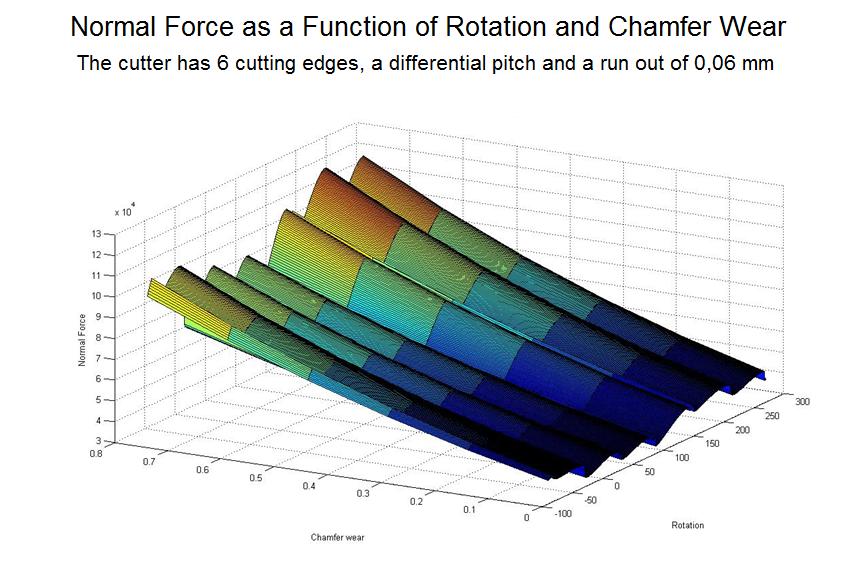

• Simulation of Stability Lobes, Cutting Forces, Torque and Power for all Types of Cutting Tools

• Control of the Dynamic Stability in Machine Tools

Milling Technology

• Calculation of Cutting Forces, Torque, Power and Stability Lobes for all Types of Milling Tools

• Reduction of Forced and Self excited Vibrations

• Differential Pitched Cutters Adopted for the Current Application

• Reduction of Thermal and Mechanical Initiated Cracks

• Optimization of the Cutting Edge Entry and Exit Regarding Fatigue and Burr Formation

• Chip Control and Chip Forming

• Optimization of Tool Paths and Engagement Arcs

Laboratory Work: planning, testing, measuring and evaluation of prototypes, current cutting tools and machine tools

• Forced Vibrations

• Stability Lobes

• Transfer Functions

• Toughness Behavior

• Fatigue

• Sound

• Chip form and Chip Control

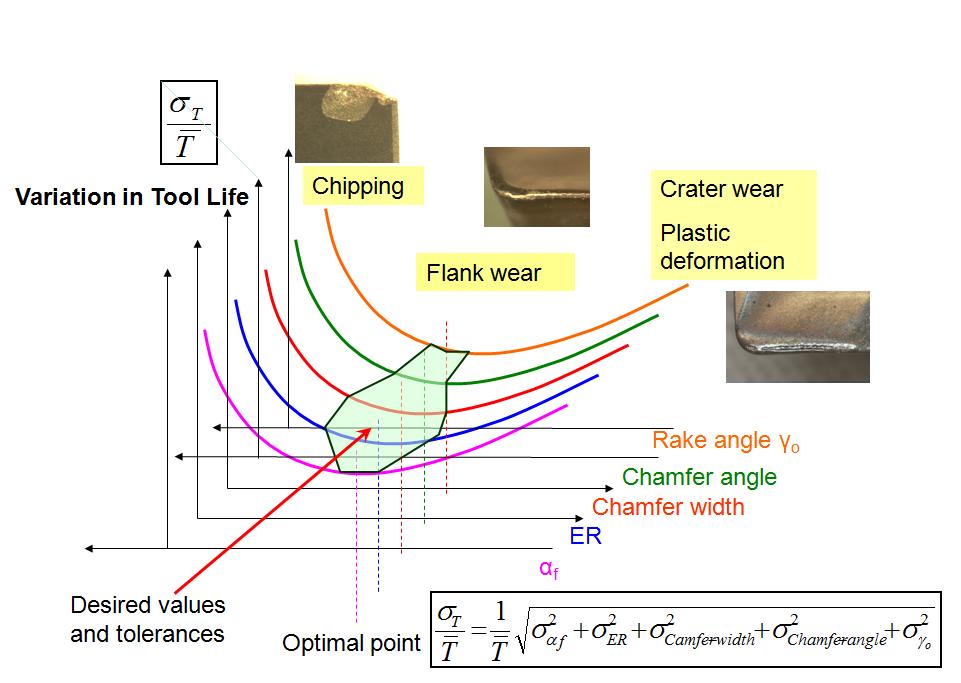

• Probability Analysis

• Tool Life and Wear Pattern

Trouble Shooting

• Reducing Disturbing Vibrations

• Suppression of Vibrations when Milling in thin Walls

• Chipping on the Wiper Flat

• BUE on the Wiper Flat in Milling

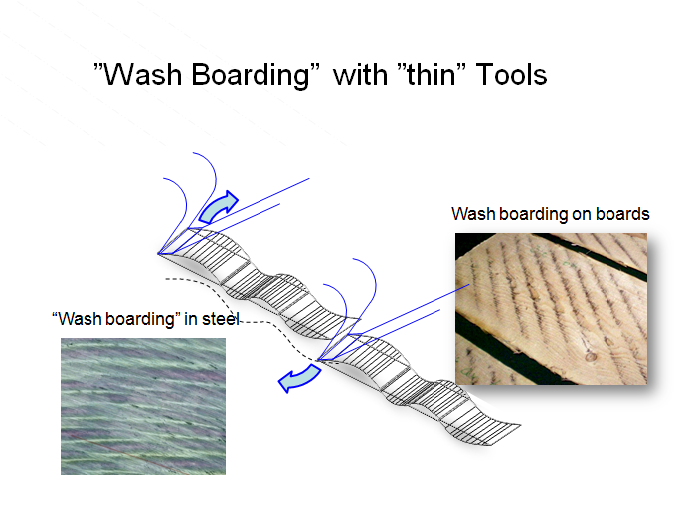

• Devastating Surface Structures

• Accuracy and Precision in Hole Making

• Over Conditioned Fixturing

• Reduction of Disturbances

Difficult to Cut Materials: Cutting Forces, Strain, Stress, Residual Stress and Temperature in the Cutting Tool and in the Work Piece

• Aluminium Alloys

• Nickel Alloys

• Titanium

• Composites

Implementation of Machining Methods

• High Feed Milling

• High Feed Milling

• High Speed Machining

• Ramping

• Heel Milling

• Plunging

• Inclined Milling

• Turn Milling

• Helix Interpolation Milling

• High Feed Helix Interpolation Milling

Economy and Tool Management

• Tooling and Tool Selection

• Optimization and Selection of Tool Sets

• Predictable and Reliable Production

• Economical Tool Life and Cutting Data

• Cost optimization

• Organization and Leadership

• Recruitments

Education for Staff Members and Education Adapted for Managers and Project Managers

Scientific Work

• Scientific Methodology, Hypothesis-Thesis-Synthesis, Scientific Problem Definitions, Problem Analysis

Vibrations and Dynamic Stability

• Cutting Forces, Fourier-Transform, Transfer Function and it´s Consequences in a Response Perspective

• System Definition, System Analysis, System Knowledge and Boundary Conditions

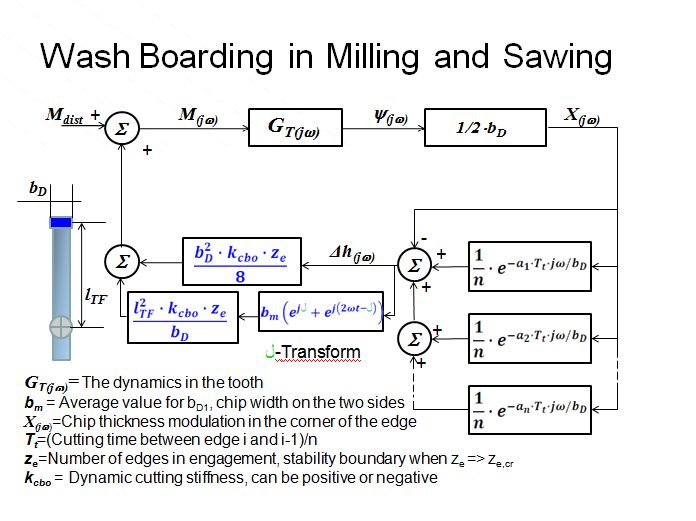

• Mechanical circuit Theory, Mode Coupling, Stability Lobes, The Nyqvist criteria, Discrete Systems, Discrete Equivalent Systems

• Spindle Dynamics, Definition of “degree of freedom” and "number of masses"

• FEM Contra Discrete Equivalent Systems with fewer Degrees of Freedom, How to Deal with non Linear Systems Regarding Machine Tools Vibrations

• Dynamic Stability in Machine Tools, Control of the Dynamic Stability in Machine Tools, How to Utilize the Dynamic Stability of Machine Tools in an Optimal way

• Dynamic Stability in Machine Tools from a Cutting Tool Perspective Regarding Design

• Dynamic Stability, Influence on the Cutting Tools Specification of Demand

Milling Technology

• Mechanics regarding the Insert Technology, Precision in the assembly, Tool life regarding plasticization and fatigue in the assembly

• Calculation of Cutting Forces, Torque and Power

• Forced and Self excited Vibrations, Stability Lobes and Differential Pitched Cutters

• Crack Propagation, Initiated by Thermal and Mechanical Load

• Fatigue Emanating from the Entry and The Exit

• Burr Generation

• Optimization of the Engagement Arc

• Chip Control and Chip Forming

• Milling in Castings, Forgings and Sheet Metal with thin Walls and how this Influence the Milling Tool Design and Machining Methodology

• Optimization of Tool Paths

• Analysis of Current Milling Cutter Designs

Laboratory Work: planning, testing, measuring and evaluation Regarding Metal Cutting

• Forced Vibrations

• Stability Lobes

• Transfer Functions

• Toughness Behavior

• Fatigue

• Sound

• Chip form and Chip Control

• Probability Analysis

• Tool Life and Wear Pattern

Trouble Shooting

• Reducing Disturbing Vibrations

• Suppression of Vibrations when Milling in thin Walls

• Chipping on the Wiper Flat

• BUE on the Wiper Flat in Milling

• Devastating Surface Structures

• Accuracy and Precision in Hole Making

• Over Conditioned Fixturing

• Reduction of Disturbances

Difficult to Cut Materials: Cutting Forces, Strain, Stress, Residual Stress and Temperature in the Cutting Tool and in the Work Piece

• Aluminium Alloys

• Nickel Alloys

• Titanium

• Composites

Implementation of Machining Methods

• High Feed Milling

• High Speed Machining

• Ramping

• Heel Milling

• Plunging

• Inclined Milling

• Turn Milling

• Helix Interpolation Milling

• High Feed Helix Interpolation Milling

Economy and Tool Management

• Tooling and Tool Selection

• Optimization and Selection of Tool Sets

• Predictable and Reliable Production

• Economical Tool Life and Cutting Data

• Cost optimization

• Organization and Leadership

• Recruitments

Predictable Tool Life:

Simulation: